Preventative Maintenance

protect your systems

Prevent breakdowns, extend equipment life, and cut repair costs with regular maintenance. Stay ahead with routine monitoring and inspections.

✅ Regular System Inspections

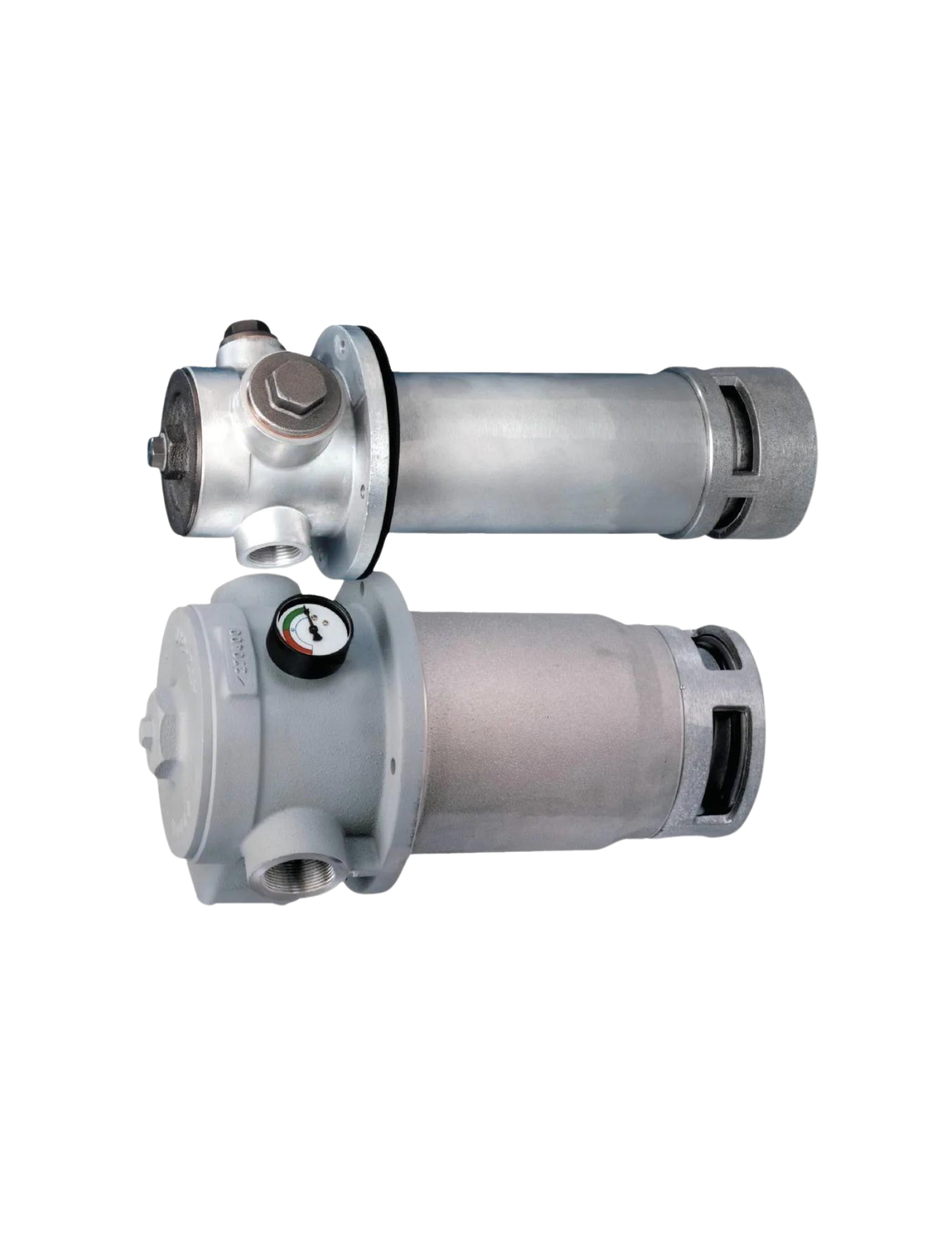

✅ Pump & Filter Inspections

✅ Oil Maintenance

✅ Fluid Analysis

✅ Filter Schedule

✅ Condition Monitoring Solutions

Get Started

Preventative Maintenance Health Checks

Preventative Maintenance Best Practices

Discover expert insights, industry trends, and application tips on Zemarc’s Blog—your go-to resource for everything fluid power, motion control, and hydraulic solutions. Stay informed with the latest updates, engineering know-how, and product innovations designed to keep your systems running at peak performance.

HYD101: Filtration & Preventative Maintenance

With long industry lead times, keep your systems optimal to prevent downtime with proper preventative maintenance practice Going over:

HYD101: Basics of Hydraulic Filters

Learn how filters work, how to increase your filter's lifespan and how to specify Hydraulic Filters

Our Preventative Maintenance Inspectors

Book Your Consultation Now

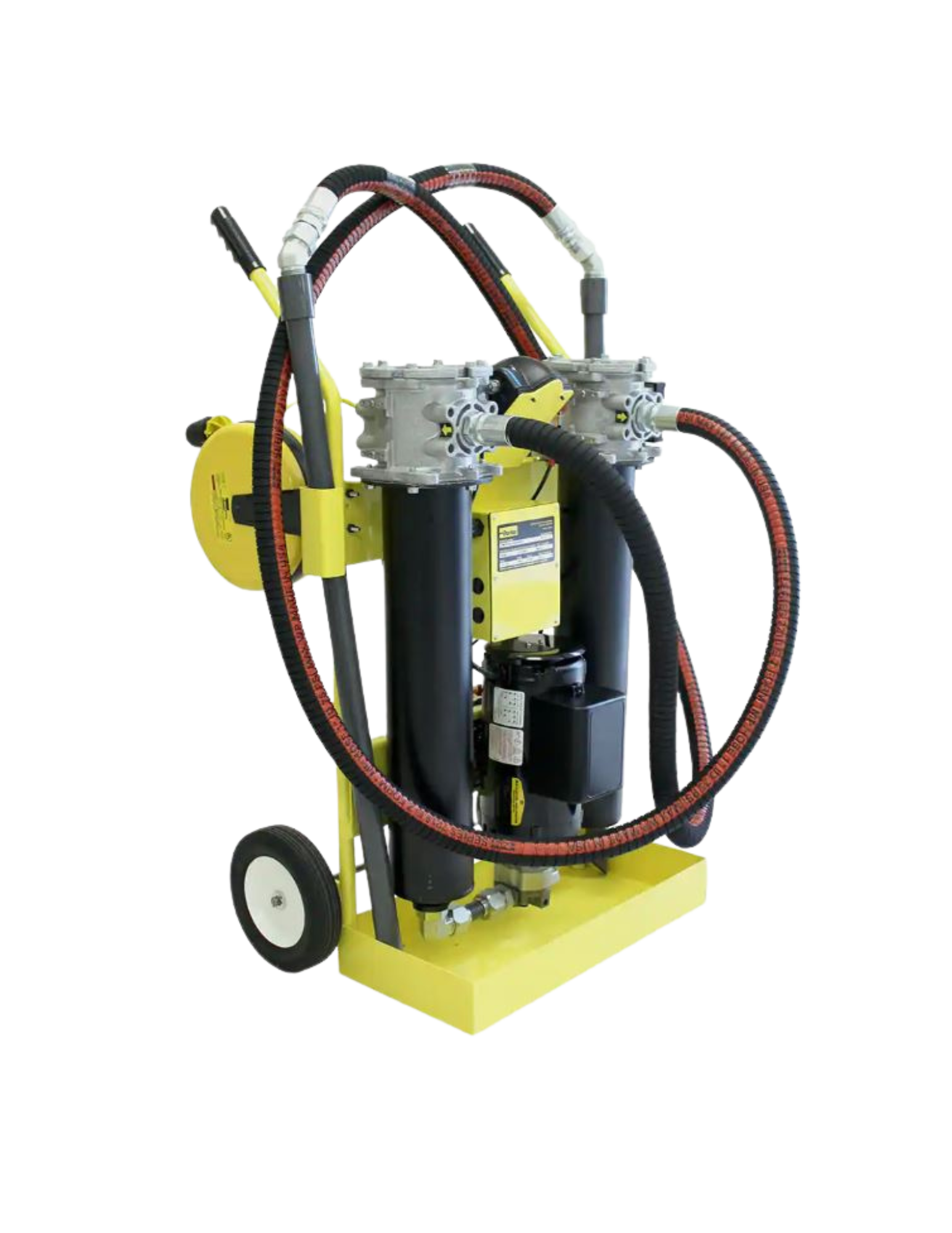

Filtration Solutions